Manidhari Foils manufactures a range of hard Aluminium in a completely hygenic condition which can effectively protect from moisture, micro-organisms, light, oxygen and other gases making it a primary material in the protective packaging of tablets, Capsules and injectables.

Thanks to the annealing temperature and final conditioning processes during its manufacturing. It is non hazardous to health, contains no plasticizers and is environmentally friendly. Coupled with flexibility and formability, the ease with which aluminium foil can be coated, printed, laminated, slitted, and cold-formed and embossed qualifies it as an extremely versatile tool for the pack designer.

UsesHard Tempered Aluminum foil coated with Heat Seal Lacquer on one side for sealing with PVC/PVDC and Clear lacquer coated on the other side for Printing

* END APPLICATIONS1.Blister Packing of Pharmaceutical Products such as Tablets and Capsules 2. Confectionery packing like Chewing Chicklets

* HEAT SEAL LACQUER OPTIONSPoly Vinyl Chloride (PVC) and Universal Lacquer

* PARAMETERSSpecification Values and Details

* Foil Thickness , Grammage & Tolerances20 Microns- 54.20 GSM (Tolerance ±8%) 25 Microns- 67.75 GSM (Tolerance ±8%) 30 Microns- 81.30 GSM (Tolerance ±8%)

* HSL Coating4 to 6 GSM OR 6 to 8 GSM (as per the customer need)

* Bond Strength with PVC or PVDC≤ 10 N (1000 grams/15 mm Strip)……(when sealed at 180°C, 0.5 second dwell time and 3-4 Bar sealing Pressure)

* Pin Hole Count20 Microns:70% of the reels with ZERO pin holes & the remaining may have maximum 10 only/ meter ² area. 25 Microns & 30 Microns: Zero Pin Holes

* WidthsUnprinted: Can be supplied in any width from 45 mm to 925mm (Wandering Tolerance±1.0mm) Printed: Can be supplied in any width from 45mm to 610mm (Wandering Tolerance±1.0mm )

* Printing Options1. Up to 8 Colours 2.Front and Back Registered 3. High Temperature Heat Resistance Printing. 4.UV Inks Printing.

* WindingUnprinted Foils: Surface for printing shall be on top side and Surface for sealing shall be on the reverse/bottom side. Printed Foils: Printed surface on the Top Side and the Sealing surface shall be on the revers/bottom side.

* IR SPECTRA Consistency 100% * Safe for Food ContactShall be in accordance with BFR XXII, FDA-175-300 &EU Directive 2002 / 72 & 2005/79.

* Core OptionsPVC/PAPER/ALUMINIUM 76.2mm±0.5mm

* Reel Outer Diameter (OD) optionsPrinted Foil: 250mm±10mm Unprinted Foils:250mm/300mm/400mm/500mm (±10mm)

* Identification DetailsEach Reel is Identified with Bar Code & with complete details of Batch Number, Product Details, Date of Manufacturing etc etc.

* PackingSafe and Sturdy Packing is ensured to withstand Transportation Hurdles

* Test CertificatesProduct Wise and Invoice Wise Certificate of Analysis with Actual Observed Values , accompanies each supply made to the customer.

Manidhari Foils manufactures aluminium foils laminated with paper for confectionery gum wrapping applications.

We are indulged in offering a broad range of Chewing Gum Wrapping Paper, which is designed in agreement with clients’ needs and requirements with use of excellent quality paper, presenting an excellent quality range of Confectionery Aluminum Foils. These Aluminum foils are manufactured by our workforce using high grade material and advanced techniques in accordance with the quality standards.

Uses:

| Industry | Usage |

|---|---|

| Food & Beverages | Dairy Products Edible Oil Fruit Juices Marine Products Processed Foods Ready to Eat Meals Snack Foods Staple Commodities Salt, Wheat flour, Rice, Sugar, etc Tea, Coffee, Spices |

| Cosmetics & Toiletries | Detergents, Face Creams, Shampoos, Tooth Paste, Mehndi |

| Pharmaceuticals | Medicines/Tablets, Oral, Dehydration Powder |

| Paper Industry | Zerox Paper Wrappers |

Manidhari Foils manufactures a range of hard Aluminium in a completely hygenic condition which can effectively protect from moisture, micro-organisms, light, oxygen and other gases making it a primary material in the protective packaging of tablets, Capsules and injectables.

Thanks to the annealing temperature and final conditioning processes during its manufacturing. It is non hazardous to health, contains no plasticizers and is environmentally friendly. Coupled with flexibility and formability, the ease with which aluminium foil can be coated, printed, laminated, slitted, and cold-formed and embossed qualifies it as an extremely versatile tool for the pack designer.

Uses:

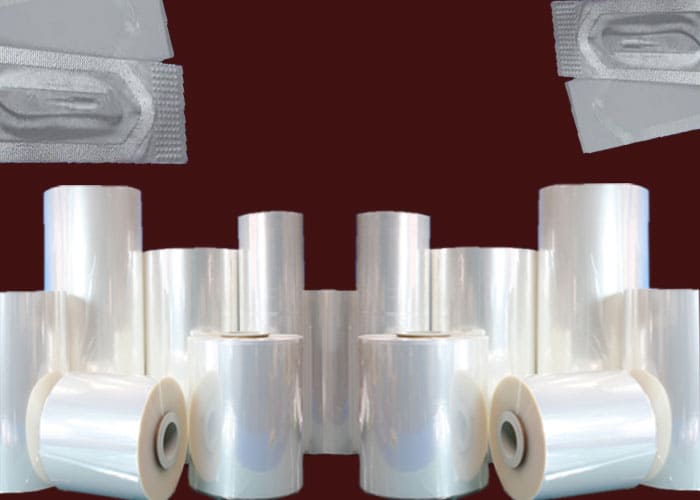

Manidhari Foils Manufactures a range of LDPE laminated soft Aluminium Foils suitable for strip packaging of products, Aluminium Strip foil is an excellent barrier to moisture, vapour and gases. It completely blocks the passage of light and entry of unwanted odours. Each Tablet is individually protected. These foils are highly recommended for packaging pharmaceutical items Such as Tablet, Capsules (Both side strip foil and in centre tablet or capsules) also Suitable for Lidding Foil in certain cases and any other use with the consent of manufacturer.

Strip Packing of Pharmaceutical Products such as Tablets and Capsules (especially of High Hygroscopic Nature)

Aluminium Blister Strip Foils Specification * NOMENCLATUREHard Tempered Aluminum foil coated with Heat Seal Lacquer on one side for sealing with PVC/PVDC and Clear lacquer coated on the other side for Printing

* END APPLICATIONS1.Blister Packing of Pharmaceutical Products such as Tablets and Capsules 2. Confectionery packing like Chewing Chicklets

* HEAT SEAL LACQUER OPTIONSPoly Vinyl Chloride (PVC) and Universal Lacquer

* PARAMETERSSpecification Values and Details

* Foil Thickness , Grammage & Tolerances20 Microns- 54.20 GSM (Tolerance ±8%) 25 Microns- 67.75 GSM (Tolerance ±8%) 30 Microns- 81.30 GSM (Tolerance ±8%)

* HSL Coating4 to 6 GSM OR 6 to 8 GSM (as per the customer need)

* Bond Strength with PVC or PVDC≤ 10 N (1000 grams/15 mm Strip)……(when sealed at 180°C, 0.5 second dwell time and 3-4 Bar sealing Pressure)

* Pin Hole Count20 Microns:70% of the reels with ZERO pin holes & the remaining may have maximum 10 only/ meter ² area. 25 Microns & 30 Microns: Zero Pin Holes

* WidthsUnprinted: Can be supplied in any width from 45 mm to 925mm (Wandering Tolerance±1.0mm) Printed: Can be supplied in any width from 45mm to 610mm (Wandering Tolerance±1.0mm )

* Printing Options1. Up to 8 Colours 2.Front and Back Registered 3. High Temperature Heat Resistance Printing. 4.UV Inks Printing.

* WindingUnprinted Foils: Surface for printing shall be on top side and Surface for sealing shall be on the reverse/bottom side. Printed Foils: Printed surface on the Top Side and the Sealing surface shall be on the revers/bottom side.

* IR SPECTRA Consistency100%

* Safe for Food ContactShall be in accordance with BFR XXII, FDA-175-300 &EU Directive 2002 / 72 & 2005/79.

* Core OptionsPVC/PAPER/ALUMINIUM 76.2mm±0.5mm

* Reel Outer Diameter (OD) optionsPrinted Foil: 250mm±10mm Unprinted Foils:250mm/300mm/400mm/500mm (±10mm)

* Identification DetailsEach Reel is Identified with Bar Code & with complete details of Batch Number, Product Details, Date of Manufacturing etc etc.

* PackingSafe and Sturdy Packing is ensured to withstand Transportation Hurdles

* Test CertificatesProduct Wise and Invoice Wise Certificate of Analysis with Actual Observed Values , accompanies each supply made to the customer.

Manidhari Foils manufactures a range of hard Aluminium in a completely hygenic condition which can effectively protect from moisture, micro-organisms, light, oxygen and other gases making it a primary material in the protective packaging of tablets, Capsules and injectables.

Thanks to the annealing temperature and final conditioning processes during its manufacturing. It is non hazardous to health, contains no plasticizers and is environmentally friendly. Coupled with flexibility and formability, the ease with which aluminium foil can be coated, printed, laminated, slitted, and cold-formed and embossed qualifies it as an extremely versatile tool for the pack designer.

Uses:Hard Tempered Aluminum foil coated with Heat Seal Lacquer on one side for sealing with PVC/PVDC and Clear lacquer coated on the other side for Printing

* END APPLICATIONS1.Blister Packing of Pharmaceutical Products such as Tablets and Capsules 2. Confectionery packing like Chewing Chicklets

* HEAT SEAL LACQUER OPTIONSPoly Vinyl Chloride (PVC) and Universal Lacquer

* PARAMETERSSpecification Values and Details

* Foil Thickness , Grammage & Tolerances20 Microns- 54.20 GSM (Tolerance ±8%) 25 Microns- 67.75 GSM (Tolerance ±8%) 30 Microns- 81.30 GSM (Tolerance ±8%)

* HSL Coating4 to 6 GSM OR 6 to 8 GSM (as per the customer need)

* Bond Strength with PVC or PVDC≤ 10 N (1000 grams/15 mm Strip)……(when sealed at 180°C, 0.5 second dwell time and 3-4 Bar sealing Pressure)

* Pin Hole Count20 Microns:70% of the reels with ZERO pin holes & the remaining may have maximum 10 only/ meter ² area. 25 Microns & 30 Microns: Zero Pin Holes

* WidthsUnprinted: Can be supplied in any width from 45 mm to 925mm (Wandering Tolerance±1.0mm) Printed: Can be supplied in any width from 45mm to 610mm (Wandering Tolerance±1.0mm )

* Printing Options1. Up to 8 Colours 2.Front and Back Registered 3. High Temperature Heat Resistance Printing. 4.UV Inks Printing.

* WindingUnprinted Foils: Surface for printing shall be on top side and Surface for sealing shall be on the reverse/bottom side. Printed Foils: Printed surface on the Top Side and the Sealing surface shall be on the revers/bottom side.

* IR SPECTRA Consistency100%

* Safe for Food ContactShall be in accordance with BFR XXII, FDA-175-300 &EU Directive 2002 / 72 & 2005/79.

* Core OptionsPVC/PAPER/ALUMINIUM 76.2mm±0.5mm

* Reel Outer Diameter (OD) optionsPrinted Foil: 250mm±10mm Unprinted Foils:250mm/300mm/400mm/500mm (±10mm)

* Identification DetailsEach Reel is Identified with Bar Code & with complete details of Batch Number, Product Details, Date of Manufacturing etc etc.

* PackingSafe and Sturdy Packing is ensured to withstand Transportation Hurdles

* Test CertificatesProduct Wise and Invoice Wise Certificate of Analysis with Actual Observed Values , accompanies each supply made to the customer.

Manidhari Foils manufactures a range of hard Aluminium in a completely hygenic condition which can effectively protect from moisture, micro-organisms, light, oxygen and other gases making it a primary material in the protective packaging of tablets, Capsules and injectables.

Thanks to the annealing temperature and final conditioning processes during its manufacturing. It is non hazardous to health, contains no plasticizers and is environmentally friendly. Coupled with flexibility and formability, the ease with which aluminium foil can be coated, printed, laminated, slitted, and cold-formed and embossed qualifies it as an extremely versatile tool for the pack designer.

Uses:Hard Tempered Aluminum foil coated with Heat Seal Lacquer on one side for sealing with PVC/PVDC and Clear lacquer coated on the other side for Printing

* END APPLICATIONS1.Blister Packing of Pharmaceutical Products such as Tablets and Capsules 2. Confectionery packing like Chewing Chicklets

* HEAT SEAL LACQUER OPTIONSPoly Vinyl Chloride (PVC) and Universal Lacquer

* PARAMETERSSpecification Values and Details

* Foil Thickness , Grammage & Tolerances20 Microns- 54.20 GSM (Tolerance ±8%) 25 Microns- 67.75 GSM (Tolerance ±8%) 30 Microns- 81.30 GSM (Tolerance ±8%)

* HSL Coating4 to 6 GSM OR 6 to 8 GSM (as per the customer need)

* Bond Strength with PVC or PVDC≤ 10 N (1000 grams/15 mm Strip)……(when sealed at 180°C, 0.5 second dwell time and 3-4 Bar sealing Pressure)

* Pin Hole Count20 Microns:70% of the reels with ZERO pin holes & the remaining may have maximum 10 only/ meter ² area. 25 Microns & 30 Microns: Zero Pin Holes

* WidthsUnprinted: Can be supplied in any width from 45 mm to 925mm (Wandering Tolerance±1.0mm) Printed: Can be supplied in any width from 45mm to 610mm (Wandering Tolerance±1.0mm )

* Printing Options1. Up to 8 Colours 2.Front and Back Registered 3. High Temperature Heat Resistance Printing. 4.UV Inks Printing.

* WindingUnprinted Foils: Surface for printing shall be on top side and Surface for sealing shall be on the reverse/bottom side. Printed Foils: Printed surface on the Top Side and the Sealing surface shall be on the revers/bottom side.

* IR SPECTRA Consistency100%

* Safe for Food ContactShall be in accordance with BFR XXII, FDA-175-300 &EU Directive 2002 / 72 & 2005/79.

* Core OptionsPVC/PAPER/ALUMINIUM 76.2mm±0.5mm

* Reel Outer Diameter (OD) optionsPrinted Foil: 250mm±10mm Unprinted Foils:250mm/300mm/400mm/500mm (±10mm)

* Identification DetailsEach Reel is Identified with Bar Code & with complete details of Batch Number, Product Details, Date of Manufacturing etc etc.

* PackingSafe and Sturdy Packing is ensured to withstand Transportation Hurdles

* Test CertificatesProduct Wise and Invoice Wise Certificate of Analysis with Actual Observed Values , accompanies each supply made to the customer.

We offer superior quality Printed Aluminium Foils in the international market. The Printed Aluminium Foils Rolls offered by us are used for safe and secure packaging of pharmaceutical products and medicines. They are accessible in customized specifications as well.

SPECIFICATION

By utilizing skills of our adroit experts, we are offering a comprehensive assortment of Printed Foils For Tablet Strips. The best grade of aluminium is used to manufacture the presented range of foil by our professionals. This foil is used for the packaging of tablets, creams and capsules. Further, this is tested for the parameters like resistant to moisture, micro-organisms, oxygen, light, temperature and other gases. Clients can avail this foil from us at market leading prices.

SPECIFICATION